Log Splitter Plans

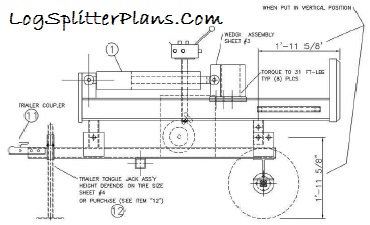

Build Your Own Home Made Hydraulic Log Splitter With Our Detailed Do-It-Yourself CAD Wood Splitter Design Plans - Vertical, Horizontal, and 3-Point

Use our build-it-yourself (DIY) log splitter plans to fabricate and assemble your own wood splitter from scratch. You can use our plans and bill of materials, or substitute materials you have around your own shop and yard to save some cash on your home made firewood splitter.

Home

Built Log Splitters offer the handyman a great way to save some money

with a do-it-yourself home project that can additionally save some money

on the heat bill for you too.

Home

Built Log Splitters offer the handyman a great way to save some money

with a do-it-yourself home project that can additionally save some money

on the heat bill for you too.

Heating with split wood as an alternative heat source can be a much more natural and economical way to warm the heart and soul. It could even add some romantic aesthetics to the room as well.

Heck, those flames may even help your significant other get heated up so that you might even get lucky as well. Now that's toasty!

Horizontal Log Splitter - vs. - Vertical Log Splitter

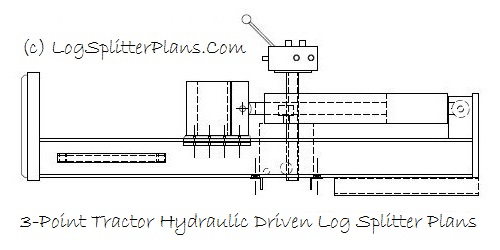

Deciding on which type of log splitter will work best for your needs is the first step to the fabrication process. Several questions should be answered before a decision is made. Horizontal, Vertical, 3-Point vertical, and 3-point horizontal.

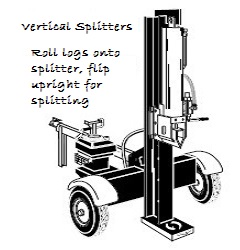

- How big is the diameter of logs being split? When you get into larger logs that are hard to lift, a vertical splitter allows you to roll logs onto the splitter foot. These logs must be flipped up on the foot plate for splitting with the downward forced wedge pressure.

- Vertical log splitters are generally designed to be used in either the horizontal or vertical position, though they are not as convenient of a layout for horizontal use as a horizontal designed splitter. This is due to the reverse log splitter design hydraulic cylinder layout pushing the wedge vs. the log.

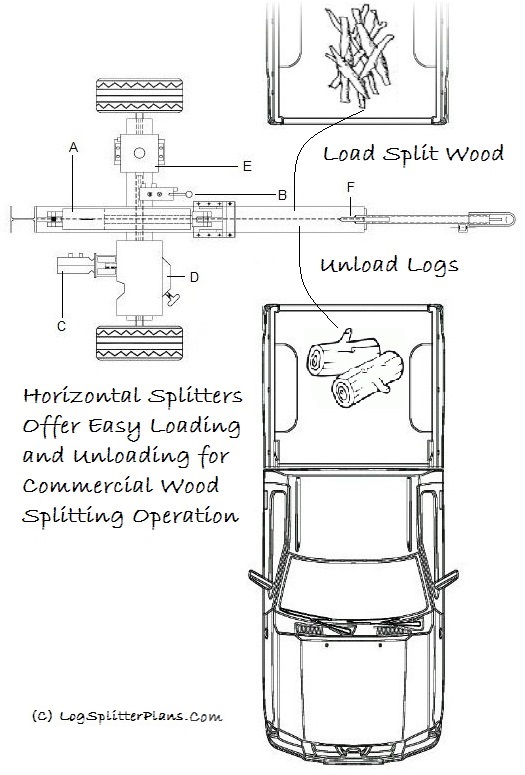

- Horizontal log splitters are usually a better choice for more commercial use. Backing trucks up to both sides allows feeding whole logs and loading split logs directly from and to the back of pickup trucks. This lowers log movement labor and increases firewood production capabilities so that more firewood can be produced in less time.

The Two Main Types Of Log Splitters

Vertical Log Splitter:

On

a vertical log splitter the pressing wedge movement comes from top down.

With the logs "standing upright" on the footplate, the wedge is forced

down through the log to be split. While this allows logs to be rolled

onto the plate for splitting, split pieces need to be picked up and

moved out of the way for continued operation.

On

a vertical log splitter the pressing wedge movement comes from top down.

With the logs "standing upright" on the footplate, the wedge is forced

down through the log to be split. While this allows logs to be rolled

onto the plate for splitting, split pieces need to be picked up and

moved out of the way for continued operation.

The one main hindrance to the wedge into log design is that at times the log being split does not separate completely and gets stuck on the splitting wedge, then it is pulled back in retract mode requiring the operator to remove the log from the wedge.

Horizontal Log Splitter:

The log splitter wedge is stationary in a horizontal direction. The log is lifted into the cradle on top of the ram beam. The hydraulic cylinder presses the log into the wedge and the split pieces fall to each side of the splitter.

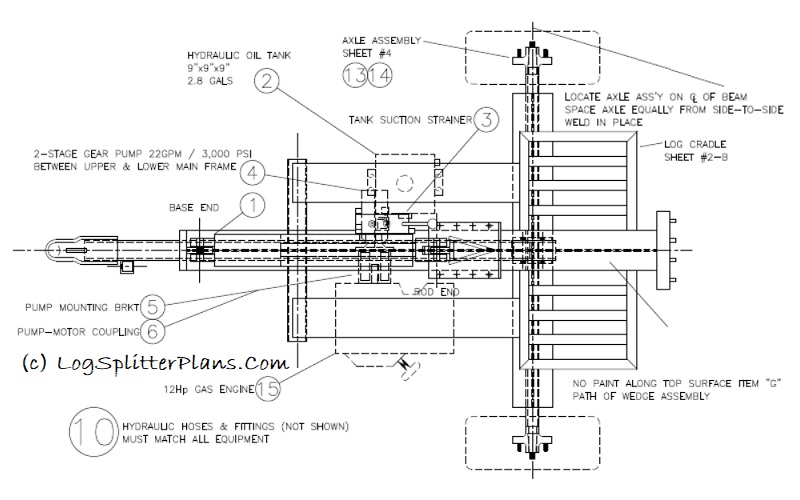

The Log Splitter Components

Log

splitters combine a number of components to form the mechanical structure

for splitting wood.

Log

splitters combine a number of components to form the mechanical structure

for splitting wood.

Many of the most common hydraulic, mechanical, and structural parts may require proper sizing to meet your work load.

Some of these components are included in the list below, and often materials you have around your shop and yard may be substituted provided they meet the structural requirements.

Calculating Proper Component Sizes

- The Main I Beam Structure needs to be strong enough to not bend

- Hydraulic Ram Cylinder needs to be the proper tonnage rated

- Hydraulic Control Valve must provide the proper functions and flow

- Hydraulic Fluid Tank needs to hold plenty of oil for sufficient function

- Hydraulic Pump should not produce more pressure than cylinder rating

- Hydraulic Fluid Filter sized to properly filter the volume of oil

- Motor - Power Source horse power hp and speed

- Pump to Motor Coupling strong enough to not break under load

- Splitting Wedge can be 2 way, 4 way, 6 way or more

The size of the cylinder effects the splitting force and speed, while the pump will effect only speed. The larger the cylinder bore, the more force or pressure it will exert to split more dense hard wood, However this requires more fluid to fill, which can make it slower.

Key factors make up the amount of force needed to split dense north American hardwoods, and control how much time is needed to do so.

Key Factors In Log Splitter Plans

- Tons of Pressure: Splitting force is the key factor for hydraulic cylinder capabilities, and the cylinder is fed by a hydraulic pump. It is imperatively important that the hydraulic cylinder be rated at or above the maximum pressure that the pump is rated for. Splitting force power is measured in tons of pressure.

- Cycle Time: This term refers to the time it take for the log splitter ram to extend out splitting the log and then return to the retracted starting position. Due to safety precautions, cycle time should be controlled to a manageable speed. A slower more controlled speed will help prevent injuries from the controlled movement of a log splitter. Other designs like flywheel splitters offer faster cycle speeds.

- Maximum Log Length: The hydraulic cylinder ramp defines how long of a log length a wood splitter can accommodate. This is an easy fabrication adjustment when building a log splitter. The length of your main beam and travel distance of your ram dictate the log splitters ability to split longer logs. Measuring the maximum length of a log that can fit into your fireplace is a good place to start. However, building a log splitter with a 24" or more length for splitting logs allows you to split up to that length, instead of being restricted to shorter logs if your design is smaller. Remember, you can cut your logs to any length, but you can't make a log splitter designed for short logs accommodate longer logs.

Home Made Log Splitters Offer Flexible Construction

With our build it yourself log splitter plans a handyman can substitute materials to fabricate and assemble their log splitter based on readily available materials they may already have. This can help lower the cost of construction and speed up the construction process.

Keep in mind that a log splitter can be a dangerous machine to begin with, and using inferior materials or shoddy workmanship can lead to injury and even death. Always consult a professional if you have questions about your materials selected, or the safe operation of these products once assembled.

The colder winter season offers a lot of challenges that can be labor intensive. If your looking to ease the work load and save some money by burning wood for heat, fabricating your own log splitter may be the answer. Heck, even if you just want to warm up the romance with a cozy fire in the fireplace, a wood splitter may be just the right answer to get that romantic mood heated up!

Buying a log splitter, or building your own wood splitter with the help of our log splitter plans can help you get all set up nice and cozy for winter!!!

Website Policies: Digital Goods and Refunds

Digital Goods: Digital Goods may include background watermark images or text such as our trademark domain name.

Digital Goods Delivery: After purchase you are redirected to the download page, and a download link is also sent to your email address registered with PayPal.

Refunds: Due to the fact that we have no control over the deletion of digital files from your device, Download Purchases for Digital Goods are Not Refundable.

We do NOT harvest, sell, or distribute purchaser data. Keep your purchase emails for reference as proof of purchase for support. Your receipt/invoice comes from PayPal.

To combat fraud, we have a system in place that records purchasers IP Address and download details. Fraudsters and scammer details will be reported to PayPal.