Log Splitter Tonnage Ratings

Choosing the right log splitter requires many questions including

- The type of splitter: vertical, horizontal, 3-point etc.

- The power source: gas, electric, hydraulic attachment

- The power or tonnage rating of the log splitter

For many manufacturers the tonnage rating on log splitters is inconsistent at best. The way they rate their tonnage from brand to brand offers way too many variables. So knowing the actual force a log splitter can provide, or tons of pressure, may be a crapshoot of a guessing game. The owners manual for the splitter you are considering may be able to shed some light.

Choosing The Right Log Splitter - Size / Tonnage

Hydraulic Log Splitter Tonnage Guide

Log size is one factor you need to consider when sizing up your log splitter. It's wise to determine what type of wood you will commonly be using, and how large these logs usually get. Determine the largest diameter log you intend to split by measuring the width. This will help determine what tonnage rating you’ll need. Log length doesn’t effect the tonnage calculation, but you do need a log splitter that with work with the standard length of log you intend to split. Generally 24" or 30" lengths, measure your fireplace to see what maximum log length can be.

General Required Log Splitter Tonnage Rating for Log Diameter and Wood Hardness.

| HARDNESS | 300-600lbs | 601-900lbs | 901-1500lbs | 1501-2200lbs |

| DIAMETER | TONS | TONS | TONS | TONS |

| 6 INCHES | 4+ | 6+ | 7+ | 10+ |

| 12 INCHES | 12+ | 15+ | 20+ | 22+ |

| 18 INCHES | 20+ | 20+ | 26+ | 26+ |

| 24 INCHES | 27+ | 27+ | 30+ | 30+ |

Hardness of a tree is primarily related to how dense the wood is. The more dense the type of wood, the more force required to split the logs.

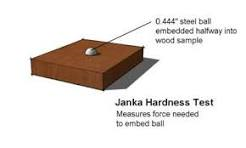

Different types of wood vary in the require pounds of force needed to split its logs. The charts below refer to the Janka test which measures the hardness of various wood species based on the pounds of pressure required to embed a steel ball half way into the wood.

Examples Of Wood Hardness Ratings

| SPECIES | FORCE | SPECIES | FORCE |

| Alder | 590 lbs | Elm | 1540 lbs |

| Ash | 1320 lbs | Fir | 710 lbs |

| Aspen | 420 lbs | Hickory | 1820 lbs |

| Basswood | 410 lbs | Locust | 1700 lbs |

| Beech | 1300 lbs | Magnolia | 1020 lbs |

| Birch | 1470 lbs | Maple | 1450 lbs |

| Boxelder | 720 lbs | Oak | 1620 lbs |

| Buckeye | 350 lbs | Pine | 860 lbs |

| Catalpa | 550 lbs | Poplar | 540 lbs |

| Cedar | 900 lbs | Spruce | 510 lbs |

| Cottonwood | 430 lbs | Sweet Gum | 850 lbs |

| Dogwood | 2150 lbs | Walnut | 1010 lbs |

This

chart is commonly referred to as the Janka Hardness Test.The Janka

hardness test measures the denting and wear resistance of different

types of wood. The test uses force to determine the pressure required

to embed an 11.28 mm (.444 in) steel ball half way into the woods surface.

This

chart is commonly referred to as the Janka Hardness Test.The Janka

hardness test measures the denting and wear resistance of different

types of wood. The test uses force to determine the pressure required

to embed an 11.28 mm (.444 in) steel ball half way into the woods surface.

This leaves an indentation in the wood half the diameter and depth of the steel ball which determines Janka Wood Hardness Ratings for wood tested.

click to open Janka wood hardness chart >

The log width and hardness is all that is required to determine what tonnage rating you will need for your log splitter.

Cycle speed and log length are other considerations that should be addressed to ensure the log splitter properly meets your needs.

These factors can be found in the owners manual or specification sheet for the log splitter you are considering.

The average rental size unit in the United States is a 26 ton log splitter.

Log Splitter Considerations

Here are some things you should look into:

- How long has the log splitter or manufacture been around? are there reviews on it?

- How readily available are parts and components for the log splitter? is it imported?

- What is the Cycle Time; how fast will it split wood and return to the start position?

- Is the motor size, pump size, and hydraulic fluid capacity properly matched for performance?

- Is the brand of the motor reputable? this can be more important than the horsepower for maintenance and parts purposes.

- Is there a warranty included? how long?

Final Notes: How Many Tons Will You Need?

The bottom line is that the tons of pressure you’ll need in your log splitter performance is directly related to the size, type, and condition of the wood you’ll be splitting. Take all the following points into consideration:

- The larger the diameter of the wood, the higher the tonnage needed

- The greener the wood (not dried) the more tons of pressure that are required to split it compared to seasoned wood (dried).

- The harder or more dense the wood is, the higher the tonnage pressure required to split it. Hardwoods (such as locust, oak and walnut) will require far more pressure than soft woods (like poplar and pine).

As a general guideline, be sure to choose a log splitter that can split the biggest, hardest, and most difficult logs that you’ll be working with.