Manual Spring Assist Log Splitter Plans

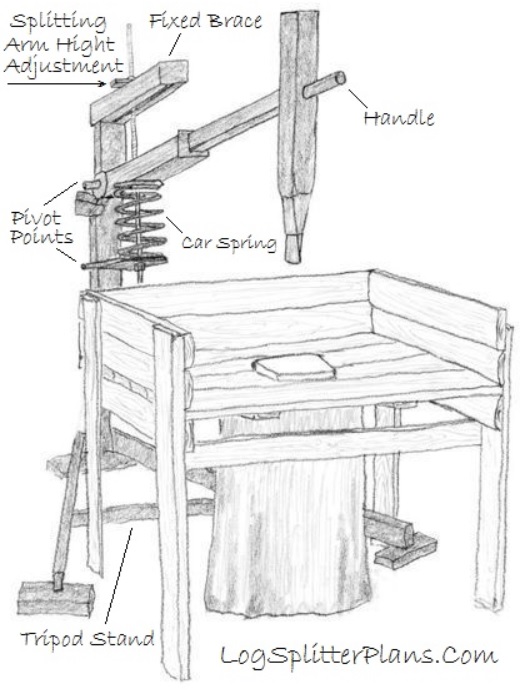

The manual spring assist log splitter is designed to be build from materials found around your workshop, scrap yard, and auto salvage parts dealer.

The main component behind the way this splitter becomes easy to use is the car spring that takes the weight off the splitting arm allowing the operator to perform splitting actions with less effort than mauls and axes.

How To Build The Manual Spring Assist Log Splitter

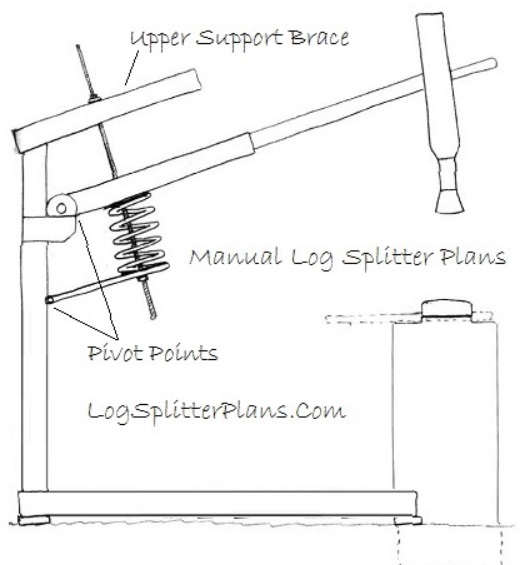

This manual log splitter design allows the adjustment of operating height through the spring bolt.

How The Spring Assist Log Splitter Is Adjusted

The spring bolt can be tightened to raise the arm, or loosened to lower the arm to proper working height for each operator, and for various log height.

The fixed upper support member provides the fixed brace point that allows the pivot points on the splitting arm, and the lower spring retention arm to be adjusted for height and log clearance.

The splitting head is made of solid heavy steel along with a wood splitter wedge used to penetrate the log for splitting.

The weight of the splitting head is the muscle behind the dominant force presented when the operator gives it a tug downward.

The spring bounces the splitting head back up for another strike if necessary for splitting.

As seen in the YouTube illustration below, this mechanical cleaver design consists of a tripod, and heavy splitter head weighing approximately 75lbs. The entire arm with cleaver plays off of the resistance of the spring as the resistance is lessened for the up-stroke for a forceful down stroke.

Powered by hand and a used car spring, you can use this splitter all day long and without your arms getting tired. Depending on the stiffness of the spring you choose, a stiffer spring should be moved back closer to the stand to get the corresponding swing frequency, and resistance.

Optional Design Stump Mount Spring Log Splitter

This design plan for a spring assist log splitter allows the unit to be mounted to a stump for secure and sturdy operation.

In this design, the spring can be pried back of forward on the support plates to adjust splitting arm height.

This system eliminates much of the bulky steel required in the tripod system design that is shown above.

With the ability to secure this spring assist log splitter to a stump, it can be set up and left to be used when needed without taking up too much space around the yard.

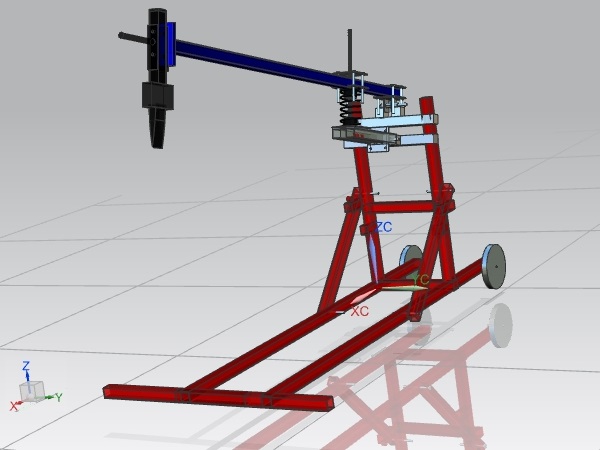

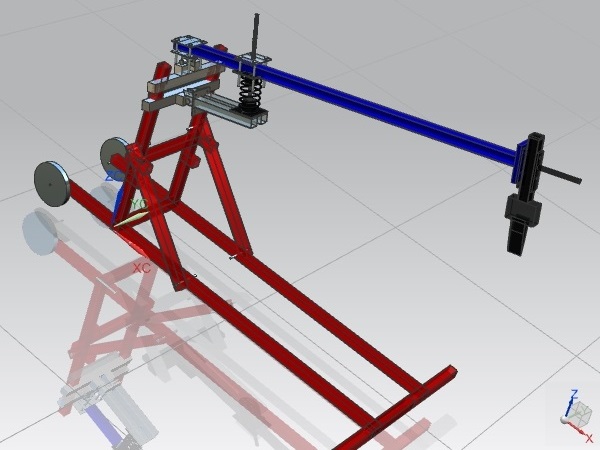

CAD Design Manual Spring Assist Log Splitter Plans

Here we have another set of CAD design plans for a spring assist log splitter that includes wheels for portability. This enables the user to move it around easily to wherever his wood pile is located.

Once moved into place, a large log is placed under the splitting head for a work height splitting table. Then other logs are placed on top of that and the splitter arm is adjusted for final log splitter work height.

With this design for a mechanical wood splitter the spring acts as an assistant like a counterbalance so you can easily, quickly without a lot of effort move the arm to split firewood.

For a low cost manual operated log splitter, this happens to be one of the best designs for conserving operator energy. Compare this to an axe, maul, or post driver splitter and you will find your production of firewood a much easier task with a device similar to these above.